How To Fix Tiles In A Swimming Pool

SwimmingPoolSteve.com is user-supported. In order to keep this resource about pools and spas available for free to all readers I earn commissions for purchases made through links on this page. For more information see the full disclaimer page. By using this website you are agreeing to the terms and conditions.

So you have a problem with the tiles in your pool. Maybe you have a few cracked tiles or chipped tiles, or more commonly you have a few that have fallen off and you

want to replace them. Before you start trying to stick the tiles back up on the wall there are a few things you need to consider - first and foremost is why did

the tiles fall off / break in the first place? If you do not address this extremely important question then it is very likely that any tiles that you repair will

simply fail again. The information on this page will teach you how to inspect for tile failure, how to fix them, and how to prevent your tiles from failing off again.

So you have a problem with the tiles in your pool. Maybe you have a few cracked tiles or chipped tiles, or more commonly you have a few that have fallen off and you

want to replace them. Before you start trying to stick the tiles back up on the wall there are a few things you need to consider - first and foremost is why did

the tiles fall off / break in the first place? If you do not address this extremely important question then it is very likely that any tiles that you repair will

simply fail again. The information on this page will teach you how to inspect for tile failure, how to fix them, and how to prevent your tiles from failing off again.

There are a number of factors that keep tiles on the wall, any of which can cause the tiles to fall off if there is a problem. What it boils down to is that if the

substrate fails (substrate is the surface the tiles are mounted on) then the tiles will fail. If the substrate cracks, the tile most likely will crack with it. If

the substrate delaminates, then the tiles will delaminate as well. In addition to these reasons for failure, improper installation is another reason why tile might

fail. When installed and maintained properly the service life of tiles is extremely long.

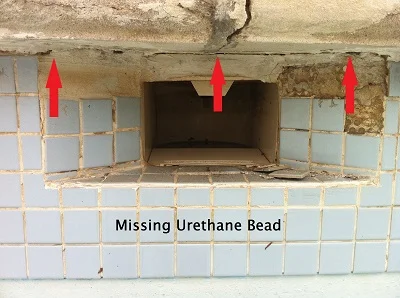

Coping Urethane Bead - If water is able to get behind the tiles this will eventually cause a failure. The coping lip of the pool is intended to provide

protection to the tiles. The single most common cause for tile failure in concrete pools is from this urethane bead failing over time and not being maintained

properly. Where the vertical tile surface meets the underside of the pool coping cantilever there needs to be a flexible, waterproof transition. Many pools

mistakenly will have a grout bead in this location which is incorrect. You can not seal these two solid surfaces with a solid connection bead - a flexible urethane

bead must be used to allow for minor movement between these two surfaces. Once the water is able to access the joint between the tiles and the coping it will begin to

deteriorate the concrete in this location. Eventually this will delaminate the tiles however pools in cold climate areas that experience freeze and thaw cycles will

fail very quickly as the water will get behind the tiles and freeze which causes the tiles to pop off.

Coping Urethane Bead - If water is able to get behind the tiles this will eventually cause a failure. The coping lip of the pool is intended to provide

protection to the tiles. The single most common cause for tile failure in concrete pools is from this urethane bead failing over time and not being maintained

properly. Where the vertical tile surface meets the underside of the pool coping cantilever there needs to be a flexible, waterproof transition. Many pools

mistakenly will have a grout bead in this location which is incorrect. You can not seal these two solid surfaces with a solid connection bead - a flexible urethane

bead must be used to allow for minor movement between these two surfaces. Once the water is able to access the joint between the tiles and the coping it will begin to

deteriorate the concrete in this location. Eventually this will delaminate the tiles however pools in cold climate areas that experience freeze and thaw cycles will

fail very quickly as the water will get behind the tiles and freeze which causes the tiles to pop off.

In the world of urethane beads and sealants there are literally hundreds of choices. Over the years I have encountered and tried dozens of different brands with varying degrees of success. The urethane that I have found that consistently outperforms every other brand is this Vulkem 116 polyurethane sealant

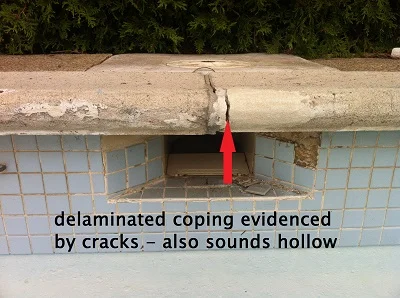

Delaminated Coping - If the coping on your pool delaminates this is another way that water will be able to find a path behind the tiles which will cause cracking, delamination and failure. Many concrete pools have a mortar set stone or cast concrete coping. As these age, sections of this coping will delaminate. This will be apparent as these sections will have movement to them when you step on them but this might not always be the case. To determine if any of your coping stones have delaminated you need to inspect them for cracks visually, as well as test them for delamination by sound. Dragging a tool such as a hammer over the coping will reveal any sections that have become detached from the top of the pool wall. Any sections that have delaminated will make an unmistakable hollow sound as you drag the head of the hammer over the surface. If you have cracked or delaminated coping stones then this will almost certainly result in tile failure in this location. If you have tiles falling off in your pool then inspect this area of the coping in particular and you are very likely to discover that the coping in this area has failed.

In order to fix delaminated coping sections you will need to cut the mortar joints on either side of the failed section. You can then remove the delaminated piece of coping. It is not uncommon that you will need to take out the failed section in pieces. Hopefully you can remove and reuse the whole coping stone section however this is not always possible. Using a grinder with a concrete cutting disc

Improper Tile Installation - Another major cause for tile failure is if the tiles were not installed correctly to begin with. The most common problem is not using a modified thin set mortar product. Many forms of concrete and mortar have the ability to hold tiles to the wall however thin set is heavily modified which makes it bond much stronger than other forms of mortar. If modified thin set is not used to set the tiles then the tiles will certainly fail early. The next most common improper installation technique is neglecting to butter the back side of the tiles before putting them up on the wall. Thin set is applied to the pool wall with a notched trowel however you must also apply thin set to the back of the tiles directly. Tiles placed without back buttering will not adhere correctly to the substrate and will be much more likely to fail. The final cause for improper installation is due to attempting to place tiles over an existing thin set layer.

Referral link from Steve that readers might want to check out: Swimming Pool Tiles You Can Order Online Right Now

How To Prepare A Pool For Tile Installation

When tiles fall off they will tend to come off cleanly. If the tiles come off clean and without taking the substrate with it this will leave a smooth and flat surface

where the tiles used to be installed. Inexperienced tile installers will take advantage of this seemingly perfect surface to install tiles on - however this is sure

to be a problem. The old layer of thin set is not a suitable surface to install tiles on. The old thin set will prevent the new thin set from adhering

properly. For mortar to adhere to a substrate water must be able to permeate the surface. The old thin set will act as a barrier and prevent the new thin set from

achieving a true bond.

In order to prevent this problem you will need to take further steps before installing new tiles. In order to ensure that the new tiles will adhere correctly you need

to chip all of the old thin set off before installing a new mud base tile preparation. Chipping the old thin set off is a time consuming and physically demanding

process but one that is critical to ensuring proper adhesion of the new tiles.

Mud Base Preparation - Mud base is another way of saying mortar base. The concrete mix for mortar base is 3 parts sharp sand to 1 part normal portland

cement. Additionally you need to add 1/3 part hydrated lime

Mud Base Preparation - Mud base is another way of saying mortar base. The concrete mix for mortar base is 3 parts sharp sand to 1 part normal portland

cement. Additionally you need to add 1/3 part hydrated lime as

well as a small amount of acrylic latex fortifier (10% of the liquid used in the mix). You need to acid wash the pool wall after chipping off the old thin set to clean all dust and debris away. usually 7 parts water to 1 part muriatic

acid is used and applied via a plastic garden sprinkler / watering can. Once you have cleaned the area you can apply a concrete bonding slurry which is a mixture of

water, portland cement and acrylic latex glue mixed to a thick molasses-like consistency. The mud base mortar is then troweled over the bonding slurry to a roughly flat

finish. You then let the mud base begin to actuate (stiffen up) before working the mud base with a sponge float

. The sponge float will help you to make the mud base perfectly flat and even as well as

leaving the mud base with a rough texture. The rough texture is important to make sure the new thin set will have good purchase. Let the mud base dry completely, a

minimum of 24 hours, before attempting to set new tiles.

If you only have a single tile to replace, or a very small failed tile section, you may be able to get away with simply using some thin set and sticking the tile back

on. The tile will be helped to stay in place by the tiles surrounding it as well as the grout application. Anything more than a very small and isolated section of

failed tile will require the mud base preparation process. The mud base process is a messy process and will result in significant staining on the interior surface of

the pool. While you can attempt to keep the interior surface of the pool protected with tarps it is common to need to resurface the interior surface of the pool after

major tile repairs.

This picture illustrates how a full tile band is typically replaced. In this particular pool the coping had failed almost completely and so a new coping was poured.

Once the new coping is in place you can do the mud base for the new tiles as you see here.

The Correct Materials For Setting Tile

Whether you are setting a single tile or re-tiling your entire pool the materials that you chose to work with with have everything to do with how well your repair works.

Many pool owners unfamiliar with tile setting will chose products like epoxy to repair tiles which is not a good choice. If you have a single tile to replace then

perhaps you can use epoxy, however thin set mortar is the product that you should be using for anything more than a single tile.

A fortified thin set mortar like this product is suitable for setting pool tiles. This product is widely available from hardware stores and online. This product represents the minimum quality level that you need to have with your thin set. Many thin set products sold in hardware stores are made for indoor tile setting applications so be sure to choose a decent quality, fortified thin set like this one.

In the world of thin set products for swimming pool tile applications there is no better product than Laticrete thin set. This is also a fortified thin set mortar however it is a much higher quality product which helps to ensure a waterproof tile application and maximum tile adhesion to the substrate. This product is also white in color which is a major advantage over grey thin set. As you set the tile on the wall you will have thin set that bleeds in between the joints in the tile. If you use grey thin set and later use a white grout for your tile you will be able to see all of the places where the thin set bled through. Matching your thin set color to your approximate grout color is a very smart move that will save you a lot of fine detail work and give you a higher quality finished look. Laticrete products like this thin set mortar are not available through hardware stores - you will need to either order it online or locate a concrete products supplier local to you that carries the Laticrete brand.

The most common grout that you should use for grouting pool tiles is a sanded grout product. Grout is available in every conceivable color so you will have a lot of options available to you. Sanded grout is suitable for slightly larger grout joints like you would have on tiles 2" big or larger. If you have tiles 1" in size or smaller you may be better off using a non-sanded grout product.

Just as with the thin set, you can spend more money on grout and get a much higher quality product. In addition to sanded grout and un-sanded grout there is also a third option which is epoxy grout. Epoxy grout is a much longer lasting and water resistant product than traditional grouts. Epoxy grout does take more effort and more time to install as well however the service life of epoxy grout is as much as 3 times as long as standard grout products.

Tiles For Use In Swimming Pools

Not any tile can be used in a swimming pool. A swimming pool is a harsh environment and the wrong tile will definitely be a problem if you use it. Typically ceramic

tiles are not used in pools. Porcelain tiles are much stronger than ceramic tiles and as a result you should always choose a porcelain tile over ceramic for

your pool.

Not any tile can be used in a swimming pool. A swimming pool is a harsh environment and the wrong tile will definitely be a problem if you use it. Typically ceramic

tiles are not used in pools. Porcelain tiles are much stronger than ceramic tiles and as a result you should always choose a porcelain tile over ceramic for

your pool.

In addition to porcelain and ceramic tiles, glass tiles are commonly used in pools. Glass tiles are amazing looking however they are as much as ten times as much

money per square foot versus entry level porcelain tiles. If you want to go with glass tiles or a glass tile mosaic in your pool then you had better be in love with

the look of them as you will certainly be paying a premium to have them. Natural stone tiles are sometimes used in swimming pools with varying degrees of success.

Natural stone which is dense is good for pool applications however lightweight or porous natural stone may not be a good choice from a longevity perspective. If you

go with natural stone be sure to choose a thin set product made specifically for natural stone installations.

Frost Proof Tile - If you are located in an area that gets below freezing temperatures then you must use a frost rated pool tile. This will drastically reduce

the amount of tile options that you have available to you. Depending on your geographic location you may have trouble finding plentiful tile options that are freeze

rated. Do not attempt to install non-freeze rated tiles on a pool in a cold climate. The tiles will most likely fail after the first freezing cycle and will

certainly not provide you with the longevity that you expect to get from a pool tile installation.

Tile setting is a skill and an art form. If you have never set tiles before it is possible that you can do this type of work successfully however you need to be

aware that you may struggle to make the tiles look as good as possible. Setting a few displaced tiles is no problem for most pool owners however installing all new

mud base and tile on your pool should probably be left to professional tile installers.

Referral link from Steve that readers might want to check out: Swimming Pool Tiles You Can Order Online Right Now

Top content from www.SwimmingPoolSteve.com

Pool and spa chemistry crash course

New pool owner guide

The Swimming Pool Steve blog

Have a question - ask Steve

Swimming Pool Steve is an award winning, second generation swimming pool specialist from Ontario Canada and one of the most trusted voices in the swimming pool industry. With over 20,000,000 views on the Swimming Pool Steve YouTube Channel, winner of the Pleatco Pool & Spa Industry Leadership award and author of hundreds of pool and spa articles both online and in print. Steve is committed to helping pool and spa owners as well as pool and spa industry workers learn more about the technical side of building, renovating, repairing and maintaining all types of swimming pools and spas. Follow Swimming Pool Steve on Facebook, Twitter and YouTube.

Paid PDF Books From Swimming Pool Steve

Steve's Pool Survival Guide

Steve's Pool Survival Guide

The Swimming Pool Steve Pool Survival Guide is intended to help pool owners understand their pool and pool equipment better, understand water chemistry, water testing and chemical corrections to the water, troubleshoot the most common pool problems and have confidence in interacting and caring for their pool in the fastest possible frame of time. Also covers pool safety, things to avoid and how to operate your pool more efficiently.

New Pool Heater Buyer's Guide

New Pool Heater Buyer's Guide

In this guide Swimming Pool Steve will help you to better understand your heater options as well as which would be best suited for your pool. Learn about BTU output and sizing of both gas/propane heaters as well as electric heat pumps for residential swimming pools. You will also learn about which specific brands and models of currently available pool heaters Steve likes to recommend. If you are thinking of adding a new pool heater to your equipment pad this buyer's guide would be a useful resource to help you make a more informed buying decision.

New Pool Installation Value Guide

New Pool Installation Value Guide

This is a value shopping guide written by Swimming Pool Steve to help home owners hiring for a new pool installation to get the maximum value for their investment with tips about how to protect your interests during the vetting, hiring and pool installation process. Anyone serious about having a pool installed will find value in this guide. Pool installers will sell the pool package that is best for them - not for you! Become an informed value shopper with this PDF guide.

Endorsed Brands From Swimming Pool Steve

The following links and products are to affiliates of the Swimming Pool Steve website. These are brands, products and services hand selected by Steve for endorsement. Please note that these endorsements can include monetary compensation, affiliate links and referral fees to Swimming Pool Steve, however there is zero additional cost to you should you use one of these products or services. Income generated from these links helps to keep this pool and spa resource available for everyone. To have your product or service considered for listing here as an endorsed brand email SwimmingPoolSteve@gmail.com.

Amazon Disclosure Statement - As an Amazon Associate I earn from qualifying purchases.

www.PoolPartsToGo.com

New Black + Decker variable speed pumps are available online from www.PoolPartsToGo.com and they are a drop in replacement for many popular pump models including Pentair Superflo and Hayward Super Pumps. With an adjustable platform base, union connections included and a very strong warranty these pumps offer an impressive value to pool owners.

- Swimming Pool Steve