How To Convert A Vinyl Pool To A Concrete Pool

SwimmingPoolSteve.com is user-supported. In order to keep this resource about pools and spas available for free to all readers I earn commissions for purchases made through links on this page. For more information see the full disclaimer page. By using this website you are agreeing to the terms and conditions.

It is not uncommon to speak with customers who are looking to convert an old vinyl liner pool into a concrete swimming pool. Usually customers are surprised to hear

just how little of the original pool can be used when converting to a concrete pool structure. I usually describe the process of converting a vinyl pool to a concrete

pool as costing the same as building a new concrete pool, plus the cost of removing an old vinyl liner pool. As much as a home owner might hope to keep the costs of the

conversion down, essentially the only potential for cost savings is on the dig itself. Depending on where you live this usually amounts to somewhere between $3000 to

$5000.

So if you already have a vinyl liner pool and it would cost so much to upgrade to a concrete pool installation, why would anyone want to convert their pool? The main

reason is property development. A vinyl liner pool is regarded as an entry level pool in the inground pool industry. When property developers buy aging homes to tear

down and rebuild with modern houses they will often look to upgrade to a concrete pool. Perhaps 20 to 30 years ago the area that you live suited a budget pool

installation. If the area has developed into a more affluent area, and you have plans to develop a property for resale, converting the pool to concrete might be a very

important design aspect to your plan. If you want to develop your property to be high end real estate then you almost have to convert to concrete as concrete pools

are the gold standard for luxury and high end swimming pool installations.

Setting Pool Elevations

When converting a vinyl pool into a concrete pool the importance of getting your elevations correct are equal to that of any new pool construction - the water level

doesn't lie so if you get it wrong you are going to have a big problem on your hands. A high quality laser transit

When converting a vinyl pool into a concrete pool the importance of getting your elevations correct are equal to that of any new pool construction - the water level

doesn't lie so if you get it wrong you are going to have a big problem on your hands. A high quality laser transit is the tool for the job for establishing batter boards on all sides of the pool. This

allows you to run string lines that establish the exact finished height that you want your concrete shell to be. Just be sure you set the height for your forms at the

height that you want the shell to be, which should be about four inches below the finished deck elevation to allow for the coping forms and deck pour.

In the concrete pool conversion pictured here, the existing walls of the vinyl pool were quite a bit lower than the planned finished deck elevation. This allowed us

to simply add to the top of the walls with our forms. The only places that we needed to cut out the galvanized steel wall was where the skimmer box would be located,

as well as the whole deep end wall of the pool as this project included an automatic pool cover.

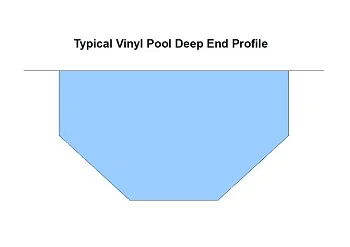

The contractor developing the property elected to keep the deep end profile typical of a vinyl liner pool as opposed to trying to dig out the bottom to give the shape

of a typical concrete pool. The area that this pool was located was all sand and trying to dig out under the walls was very likely to open a can of worms that could

see the whole hole destabilize.

Skimmer Box Installation

When you set up the batter boards and establish the height for the shell forms there is a little bit of wiggle room for the height since you can slightly vary the

coping height to account for minor variances. The skimmer height will ultimately dictate the height of the water level in your pool. If you are going to make a

mistake that you wish you had not, this is it. If you were to mount the skimmer too high or too low by even a few inches the entire water level of the pool will be

wrong.

As discuss in this article on how to install a pool skimmer there are quite a few major differences in how a skimmer is installed on a vinyl

pool versus how you would install a skimmer on a concrete pool. A vinyl pool skimmer is attached to the wall panel of the vinyl pool kit with screws. Other than this

there is no supporting structure that attaches the actual skimmer itself to the pool. A concrete pool skimmer needs to be permanently attached to the pool wall and

the way that you accomplish this is to encase it completely in a solid cube of concrete on all sides.

This effectively anchors the skimmer and makes in a part of the pool shell structure. If the pool were to shift, lift or sink then the skimmer would also do so with

the pool. If you were to leave the skimmer unanchored to the pool wall then it is very likely that a leak would develop where the skimmer meets the pool wall as the

pool and the earth surrounding the pool would move at different rates. With the skimmer surrounded by dirt it would have no choice but to move if the ground moves,

and if the pool moves then the ground prevents it from moving along with the pool.

Steel Rebar Grid Installation

The rebar grid installation requirements for building a concrete pool vary depending on your geographic location. For this pool an engineer was hired to establish

soil stability, rebar and bond beam specifications as well as concrete requirements for the pool. In many areas this would be considered standard protocol for any

concrete pool construction. There are however still many notable locations that have little to no requirements for engineered plans for building concrete pools. The

total cost to the engineering firm for this documentation and some field inspections was around $1000 to $1500 dollars.

The bond beam was established to be 12" thick concrete with a heavy steel box beam within it. The box beam consisted of four 15mm bars wrapped in 10mm ties every 12".

The remaining structure was 10mm rebar tied in an 8" grid with a double thick mat on the deep end wall where the autocover box was located. The extra angles and

contours of the vinyl pool floor and slopes will take longer to install the rebar than what a concrete pool would normally take. The steel was tied at every second

intersection with standard rebar tie wire. Some pool builders prefer to use a tie wire twister

Shotcrete Application For Concrete Pools

Much like the steel layer, the concrete application for building pools will vary depending on your geographic location. In some areas a dry pumped shotcrete (often referred to as gunite) is more popular and in others wet pumped shotcrete as pictured here is more popular. There are also many builders who cast concrete pools which means that they do not shoot them and hand trowel, but instead build an inside form in addition to the backside form allowing to pour and vibrate the entire pool.

Shotcrete applications require some very skilled and experienced workers. I can not imagine anyone wanting to take on a shotcrete project unless they are specifically experienced with this process. In many areas the concrete is actually subcontracted to a third party company, but as with most subcontracting arrangements this can potentially lead to a reduction in quality of the project as a whole. Still, if you don't have the skills, or the employees to shoot a pool, then you don't have many other options unless you are very handy with concrete forming. A form and pour concrete pool requires more skill when it comes to carpentry and form building, but less skill on concrete day when compared to shotcrete methods.

In the right hands a shotcrete nozzle looks easy enough to handle. In reality you need to be big, and strong, and maybe a little crazy to be a nozzle man. If the

pump operator has the pressure up high the nozzle would have enough strength to lift a 150 pound person off the ground...assuming they had the strength to hang on to it

at all. As it turns out, a shoulder mounted concrete cannon is just as formidable as it sounds.

In the right hands a shotcrete nozzle looks easy enough to handle. In reality you need to be big, and strong, and maybe a little crazy to be a nozzle man. If the

pump operator has the pressure up high the nozzle would have enough strength to lift a 150 pound person off the ground...assuming they had the strength to hang on to it

at all. As it turns out, a shoulder mounted concrete cannon is just as formidable as it sounds.

The process of pumping semi-solid concrete through high pressure hoses can go from business as usual to catastrophic injury or death in an instant. The biggest concern is that there is a pump the size of a dump truck applying pressure to the lines. If the line were to become kinked, or should a piece of aggregate get lodged in the nozzle, the pump operator has about one second to shut off the pressure before bad things can start to happen. Having chunks of aggregate larger than what should be there coming from a shotcrete nozzle is sure to illicit a lot of yells and curses from the shotcrete crew. If a pump operator were not paying close enough attention and allowed a blockage in the nozzle to spike the line pressure, the concern is that the line will clear itself - and send the nozzle operator flying in the opposite direction. I have seen a blocked nozzle shoot a 400+ pound man straight backwards across the pool when it popped. A reliable shotcrete mix, and a trustworthy and attentive pump operator are critical for the safety of any shotcrete application.

Coping, Tile & Plaster

Once the pool shell has been installed it will need to cure for 30 days before you can proceed with the final stages which are coping, tile and plaster installation.

At this point in the conversion this pool is now effectively a concrete pool. The coping forms, mud base, tile and interior surface installation process will again

depend on where you are located geographically. In some areas cast coping is popular, where in other areas natural stone coping is more popular. In cold climate

areas only frost rated pool tile can be used, usually porcelain or glass, with natural stone tile being a more popular option in recent years. A high quality glass

tile is probably the most desirable, and expensive, tile option in pools.

The interior surface of the pool is finished with a dense mortar that is very water resistant that is hard troweled to a glossy smooth finish. There are many other

interior surface options that have become popular in recent years that include colored aggregates, pigments and exposed aggregates. Paint is another option for the

interior surface of concrete pools however most experts would agree that all paints are inferior to cementitious finishes. If you are converting a vinyl pool to a

concrete pool for the purposes of developing a high end real estate property, then paint is certainly not the finish you want in your pool. If you could choose any

interior surface and cost was not an issue, then a properly installed all-tile interior surface is the best pool coating that money can buy. The only reason that

all-tile interior surfaces are not more popular is simply that it is significantly more expensive than other interior surface options - more than ten times as much

money.

Converting a vinyl pool to a concrete pool is not something that you will see done very often. For much less money this pool could have been reconditioned as a vinyl pool however functional usage is not everything. Sometimes the design calls for converting the pool even if it does cost many times more than a vinyl remediation project. It is far more common to see concrete pools that get converted to vinyl liner pools but that is an entirely different process.

With a vinyl to concrete pool conversion the only down side is that it costs a lot of money. With the reverse project, a concrete pool converted to a vinyl pool, the same can not be said. I quite often speak with concrete pool owners looking for a cost-effective solution to renovating their aging concrete pool. Some installers suggest that hanging a vinyl liner in a concrete pool is a good idea...but I would tend to disagree. If you would like to learn why, then read this article about can you put a liner in a concrete pool?

Top content from www.SwimmingPoolSteve.com

Pool and spa chemistry crash course

New pool owner guide

The Swimming Pool Steve blog

Have a question - ask Steve

Swimming Pool Steve is an award winning, second generation swimming pool specialist from Ontario Canada and one of the most trusted voices in the swimming pool industry. With over 20,000,000 views on the Swimming Pool Steve YouTube Channel, winner of the Pleatco Pool & Spa Industry Leadership award and author of hundreds of pool and spa articles both online and in print. Steve is committed to helping pool and spa owners as well as pool and spa industry workers learn more about the technical side of building, renovating, repairing and maintaining all types of swimming pools and spas. Follow Swimming Pool Steve on Facebook, Twitter and YouTube.

Paid PDF Books From Swimming Pool Steve

Steve's Pool Survival Guide

Steve's Pool Survival Guide

The Swimming Pool Steve Pool Survival Guide is intended to help pool owners understand their pool and pool equipment better, understand water chemistry, water testing and chemical corrections to the water, troubleshoot the most common pool problems and have confidence in interacting and caring for their pool in the fastest possible frame of time. Also covers pool safety, things to avoid and how to operate your pool more efficiently.

Salt Water Recommendations

Salt Water Recommendations

Are you considering upgrading to salt water in your pool? In this paid PDF Steve talks about which pools should avoid using salt water. Find out concerns about using salt in your pool but also the potential benefits of salt water. Finally hear which specific brand and model of salt chlorine generator Steve thinks is the best option currently available to pool owners and how to choose the right size salt system for your pool.

New Pool Heater Buyer's Guide

New Pool Heater Buyer's Guide

In this guide Swimming Pool Steve will help you to better understand your heater options as well as which would be best suited for your pool. Learn about BTU output and sizing of both gas/propane heaters as well as electric heat pumps for residential swimming pools. You will also learn about which specific brands and models of currently available pool heaters Steve likes to recommend. If you are thinking of adding a new pool heater to your equipment pad this buyer's guide would be a useful resource to help you make a more informed buying decision.

New Pool Installation Value Guide

New Pool Installation Value Guide

This is a value shopping guide written by Swimming Pool Steve to help home owners hiring for a new pool installation to get the maximum value for their investment with tips about how to protect your interests during the vetting, hiring and pool installation process. Anyone serious about having a pool installed will find value in this guide. Pool installers will sell the pool package that is best for them - not for you! Become an informed value shopper with this PDF guide.

Endorsed Brands From Swimming Pool Steve

The following links and products are to affiliates of the Swimming Pool Steve website. These are brands, products and services hand selected by Steve for endorsement. Please note that these endorsements can include monetary compensation, affiliate links and referral fees to Swimming Pool Steve, however there is zero additional cost to you should you use one of these products or services. Income generated from these links helps to keep this pool and spa resource available for everyone. To have your product or service considered for listing here as an endorsed brand email SwimmingPoolSteve@gmail.com.

Amazon Disclosure Statement - As an Amazon Associate I earn from qualifying purchases.

www.PoolPartsToGo.com

New Black + Decker variable speed pumps are available online from www.PoolPartsToGo.com and they are a drop in replacement for many popular pump models including Pentair Superflo and Hayward Super Pumps. With an adjustable platform base, union connections included and a very strong warranty these pumps offer an impressive value to pool owners.

- Swimming Pool Steve